Nut

Essential Industrial Nuts for Secure Assembly

Secure your connections with our extensive selection of industrial nuts, engineered for reliability in every turn. From standard hex nuts to specialized self-locking varieties, we supply premium stainless steel and high-strength carbon steel options. Fastener Core serves both large-scale manufacturers and individual projects with flexible, cost-effective procurement solutions.

- Material Variety: Stocking Stainless Steel (A2/A4) for weather resistance and Carbon Steel (Grades 8/10) for structural loads.

- Volume Tiered Pricing: Access competitive wholesale rates for bulk pallet orders or purchase smaller packs for maintenance.

- Global Logistics: We provide professional international shipping via sea, air, and land to ensure a stable supply chain.

Overview of Our Nut Collection

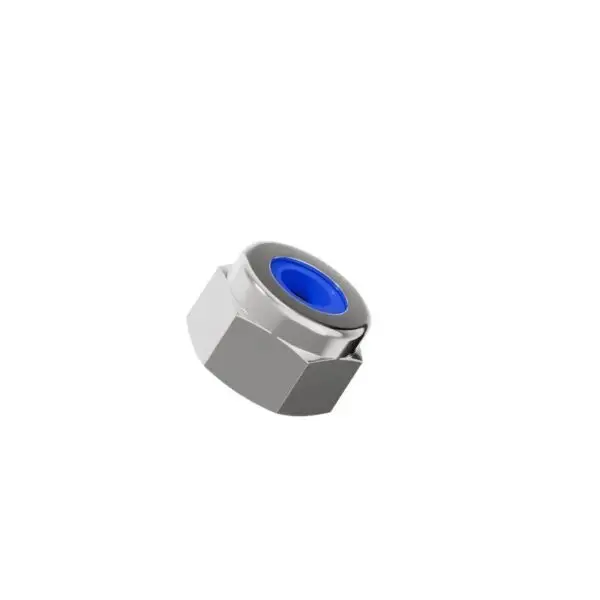

Nuts are the counterpart to bolts and screws, providing the clamping force necessary to hold machinery and structures together. Our catalog encompasses a broad spectrum of types, including Hex Nuts for general fastening, Nyloc Nuts for vibration resistance, and Flange Nuts which distribute pressure over a wider area. We ensure that every nut we supply meets rigorous industrial standards for thread fit and proof load.Material and Strength Grade Guide

To prevent thread stripping or assembly failure, the nut must always be equal to or stronger than the bolt it is paired with. Below is a guide to our primary material offerings and their strength classifications.| Material Type | Common Grades | Key Characteristic | Typical Application |

|---|---|---|---|

| Stainless Steel | A2 (304), A4 (316) | Excellent corrosion resistance; Non-magnetic (mostly). | Chemical processing, marine environments, outdoor fixtures. |

| High Tensile Steel | Class 8, Class 10 | High proof load; heat-treated for strength. | Automotive suspension, structural steel beams, heavy machinery. |

| Mild Steel | Class 4 | Ductile and cost-effective. | Light duty assembly, furniture, non-critical joints. |